Three Layers Co-extrusion Blown Film Machine Set(with haul off rotary and IBC Inner bubble Cooling System)

- FOB Price

US $800000.001 - 10 set

- group name

- Coextrusion Blown Film Machine

- Min Order

- 1 set

- brand name

- Zhuxin Paper bag machine ,film blowing machine

- model

- 3SJ-50/65

- Nearest port for product export

- Ningbo Sea Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Have the independent export and import right

- update time

- Sat, 18 Jul 2015 15:33:38 GMT

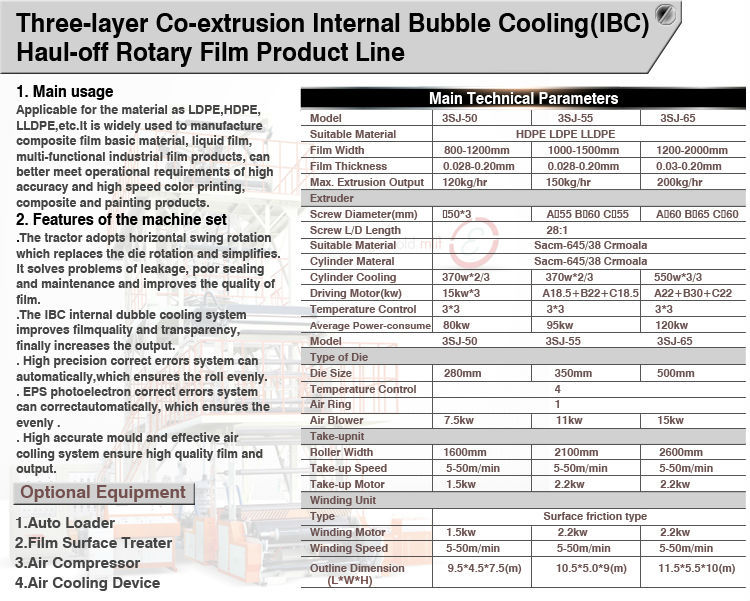

Paramtents

Function High Output 3 Layer Blown Film Coextrusion Machine

Rotary Die Part Haul Off Rotary

Double Winding Part Automatic Changer Rewinder

IBC Included

Inverter Yaskawa

Main Motor Simens

Temperature control Omron

Electric Schneider

Air Cooling Depend on customers' requirement

Gear Box with Air Pump Xiaoshan Shuguang Factory

Packging & Delivery

-

Min Order1 set

Briefing

1.three layer Blowing Film Machine

2.width:2000mm ,high speed 200kg

3.haul off rotary ,automatic winder

Detailed

1.three layer Blowing Film Machine

2.width:2000mm ,high speed 200kg

3.haul off rotary ,automatic winder

Three layer Film Blowing Machine (3SJ-50/65)

Feature:

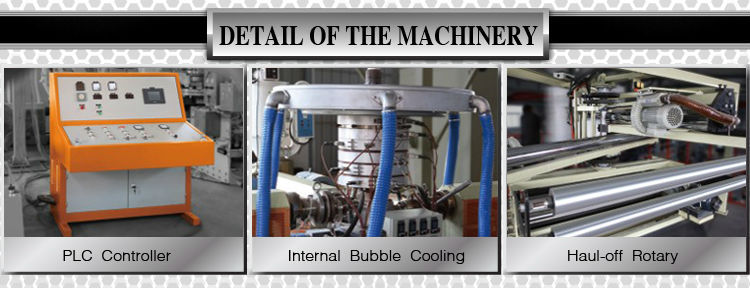

1.Haul-off unit is oscillating reverse by horizontal±180。.Its structure is reasonable, so it economizes lots of energy and it is easy to maintain. By means of the reversing haul-off unit, films can be produced without requiting rotating die head, so the structure of die head is simplified. Reversing haul-off unit eliminates many problems of ling channel for the rotating die head, difficult sealing for the melt, compound leakage being easy, unsymmetrical heating, difficult maintenance, macro film tolerance and so on Haul-off unit reduces the degree of difficulty for recipe of the multi-layer co-extruded product and production technical processing control, if the blowing film line is with IBC (Internal Bubble cooling system),it can produce film with the quality of more high-grade transparency and better all round performance. The produced film is very flat, reel is high-quality by the use of reversing haul-off units. The film can meet the demand for the high-speed printing.

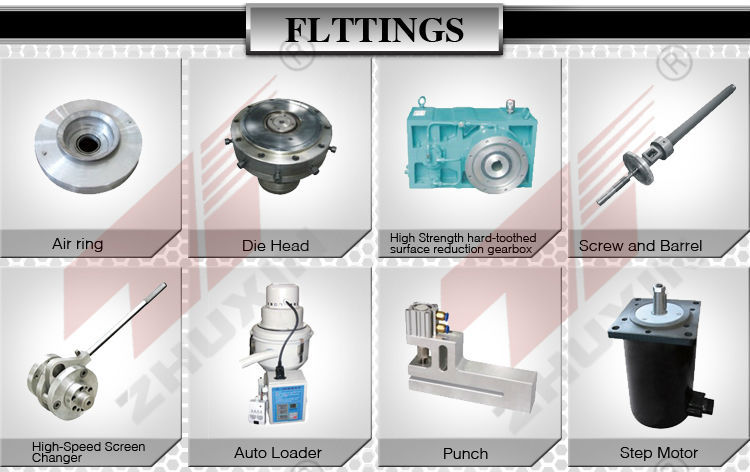

2. This machine set is to satisfy the customer’s requirements of high quality, high out put film blowing equipment. It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, IBC inner cooling system, fully automatic surface friction type double cut double winders, computer concentrate control system, advanced technique and equipments. Compare with kindred equipment, it has the advantages such as more compact structure, higher output, better produce quality, less energy consume, easier operation. It can be widely used into various kind of high transparence packing film manufacture, and create the considerable economic benefit for you.

The main engine parts:

The main engine parts:

Automatic double winder :

Automatic double winder :

Zhuxin Machinery Sales Tern :

Zhuxin Machinery Sales Tern :

Contact Person : Ms Marina

+86 13757727977 ( Viber / Whatsapp / Line available )